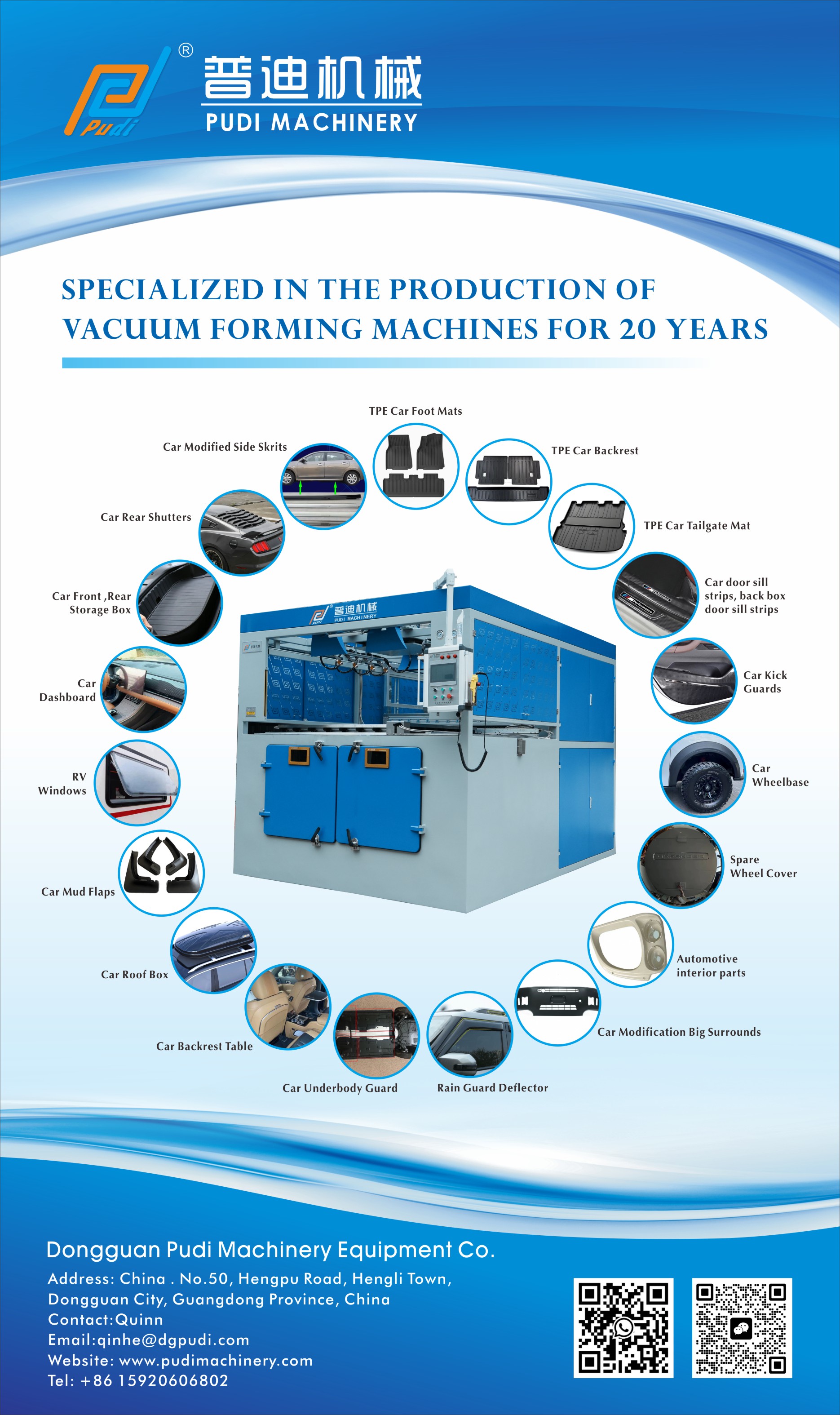

Pudi's Thick Sheet Vacuum Forming for Locomotive Parts: Expanding Possibilities

Introduction: Vacuum forming has revolutionized how locomotive parts are produced, especially when it comes to complex and durable components. As technology continues to evolve, the demand for thick sheet vacuum forming increases, paving the way to greater precision and functionality. This article explores the expansive areas of application for locomotive parts, highlighting the importance of Pudi’s thick sheet vacuum forming solutions. Whether you’re in product design, manufacturing, or simply curious about how modern transportation components are made, read on to discover a new dimension of efficiency and reliability.

1. Enhanced Structural Integrity

In the locomotive industry, structural integrity is paramount. Locomotive parts must withstand high levels of stress, vibration, and extreme weather conditions. By using thick sheet vacuum forming, manufacturers can create components with increased rigidity while maintaining relatively low weight. This improved structural strength benefits train exteriors, interior panels, and various load-bearing components. In fact, Pudi's thick sheet vacuum forming areas of application for locomotive parts have demonstrated optimal strength in producing large-scale panels and advanced composite structures that stay durable through years of use.

2. Precision Forming for Interior and Exterior Components

One of the biggest challenges in locomotive manufacturing is maintaining tight tolerances across various interior and exterior parts. With advanced vacuum forming technology, suppliers can achieve consistent thickness and design accuracy. Locomotive window frames, seating shells, roof panels, and interior cladding all benefit from using thick sheet vacuum forming. This precision ensures the best fit and finish, enhancing both functionality and aesthetics. Pudi’s technology supports these requirements by offering versatile solutions for different train segments—providing consistent output for a variety of design specifications.

3. Weight Reduction and Fuel Efficiency

Locomotives consume considerable energy over their lifespan. Even a small reduction in overall weight can translate into significant cost savings and lower emissions. Thick sheet vacuum forming addresses this issue by making it possible to produce lightweight yet robust components. The thin-walled yet structurally strong panels can replace heavier metal parts. Moreover, modern resins and composites used in thick sheet vacuum forming maintain high stiffness without compromising design freedom. Hence, operators not only save on operational costs but also reduce their carbon footprint, making locomotive travel more sustainable.

4. Corrosion Resistance and Longer Service Life

Compared to metal parts, vacuum-formed plastic and composite pieces often resist corrosion far better, especially in environments prone to humidity or extreme temperature fluctuations. By switching to advanced polymers and high-tech thermoplastic sheets, locomotive parts can enjoy extended service life and reduced maintenance. Pudi’s specialized vacuum forming methods help guarantee that the final product is both waterproof and corrosion-resistant, which is crucial for locomotive components exposed to the elements.

5. Streamlined Production and Cost-Effectiveness

Thick sheet vacuum forming offers a faster production cycle than many traditional fabrication methods, thanks to optimized heating, forming, and cooling processes. This streamlined approach helps keep costs down—even for short-run production or custom parts. Furthermore, fewer secondary operations are needed, reducing lead time and labor expenses. Because Pudi’s machines are built with reliability and efficiency in mind, manufacturers enjoy shorter turnaround times and a consistent, high-quality output that meets locomotive industry standards.

6. Future Innovations and Industry Growth

The locomotive sector is continually adapting to new technologies to meet global demands for reliability, safety, and eco-friendly solutions. From automated production lines to digitally controlled processing parameters, vacuum forming remains at the forefront of these innovations. As the market grows, so does the variety of specialized tools and materials offered by Dongguan Pudi Machinery Equipment Co., Ltd.. Their commitment to research and development ensures the vacuum forming machines stay aligned with emerging engineering standards and environmental regulations around the world.

Conclusion

Pudi’s thick sheet vacuum forming technologies have opened the door to advanced locomotive part production, enabling stronger, lighter, and more durable components. Whether you need complex interior elements or large exterior panels, the reliability of vacuum forming underpins the modern train industry’s demands. As sustainability and energy efficiency priorities continue to rise, thick sheet vacuum forming stands out as a powerful solution for next-generation locomotive design.

If you would like to learn more about how Dongguan Pudi Machinery Equipment Co., Ltd. can streamline your production process with state-of-the-art vacuum forming machines, visit their official website at www.pudimachinery.com or reach out via phone at +86 15920606802. Their extensive experience and dedication to innovative machinery manufacturing are ready to support your projects.